6th km Charilaou-Thermi Rd

SURPLAS - A Sustainable integrated Route to convert waste PLAStics to H2 and low carbon liquid fuels

More About Us

Plastic Waste to Sustainable fuels

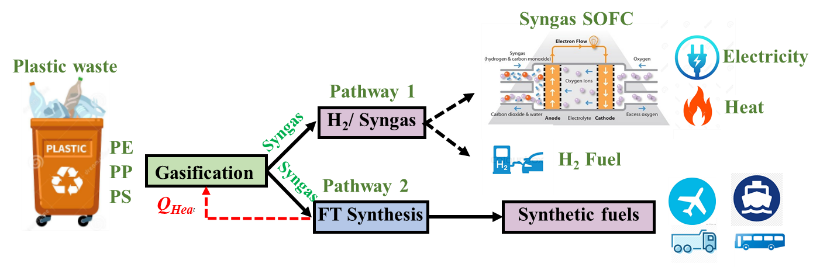

SURPLAS aims to deliver an integrated solution utilizing plastic waste to generate low carbon H2 and liquid fuels providing a decarbonisation route for the stationary power generation and transport sectors toward a clean energy and sustainable future.

By introducing a breakthrough technology on waste-driven fuel production, SURPLAS technology will strengthen EU industries competitiveness and create market opportunities and employment in the vital sectors of eco-friendly/efficient energy production and waste utilization across EU.

Waste plastics

Gasification

Low carbon transportation fuels

Fischer-Tropsch

Catalysis

Circular Economy

SURPLAS

The challenge

In 2019, 368 mtn of plastic waste was generated globally, with the EU alone generating more than 29.1 mtn of post-consumer plastic waste per annum . Of this, around 32.5% is recycled, 42.6% is managed by energy recovery processes, mostly incineration, and the remainder is landfilled. Incinerating plastics can cause several environmental issues, such as dioxins and other toxins formation causing adverse health issues. Additionally, plastics can end up in the oceans negatively affecting the marine ecosystems, if not disposed of properly. Thermochemical conversion technologies, such as gasification and pyrolysis, have gained significant attention for the management/energy recovery of/from plastic waste since conventional mechanical recycling techniques cannot recycle all types of plastic waste due to their contamination with food, dirt, paper labels, and polymer mixtures that makes them an attractive alternative.

The Solution

SURPLAS will simultaneously deliver a step change and innovative improvement in the production of low carbon fuels and plastic waste management, an integrated solution from feedstock to end use.

Gasification of waste plastics is a key enabling route for low carbon H2/syngas generation. A range of plastic waste will be explored, while use of the produced syngas will be examined as feedstock in Fischer Tropsch (FT) reactors toward gasoline and diesel mixtures (low carbon liquid fuels) going beyond current state of the art. In both cases, optimum processing conditions and catalysts will be defined to maximise performance. Lab-scale gasifiers and the 1 kg/h fully automated gasification unit in CPERI will be used to determine the optimum process parameters for gasification. In addition, the upgrading of syngas mixtures produced from plastic waste, will be explored in a pressurized lab-scale FT catalytic reactor to generate liquid fuels. The energy and heat integration of the overall process design and its viability for real scale applications will also be investigated.

Few more words

SURPLAS concept and potential applications

We envisage SURPLAS will both demonstrate the feasibility of this innovative technology at the same time as paving the way for future applications. The scope is in line with the European Union’s Strategy for Plastics in a Circular Economy and serves the ultimate goal of the European Green Deal toward an energy transition to a low or even zero carbon economy. Apart from the obvious clean energy prospects and environmental-circular benefits, SURPLAS also offers a unique thermal integration between the endothermic gasification of waste plastics and the exothermic hydrogenations within the Fischer Tropsch (FT) process.

SURPLAS project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No101068372.

Call: HORIZON-MSCA-2021-PF-01

Topic: HORIZON-MSCA-2021-PF-01-01

Type of action: HORIZON TMA MSCA Postdoctoral Fellowships - European Fellowships

Granting authority: European Research Executive Agency

Do you require more information?

Contact us!

News & Updates